Nes India Engineers are the most leading Manufacturers, Suppliers, Exporters of Shell Heat Exchanger in Mumbai. Nes India Engineers is a company that manufactures shell and tube heat exchangers. They have been in the business for over decades and have garnered an impeccable reputation for their quality products. The Shell Heat Exchanger Manufacturers has been designed by our company to help you through your day-to-day activities easily and without any trouble.

The company is based in Pune and has its manufacturing unit there as well. This allows them to provide the best of service to their customers. They are also equipped with the latest machinery for better quality products.

Shell Heat Exchangers are designed to transfer heat from one fluid to another. They are used in a variety of industries, such as power plants, petrochemicals, pharmaceuticals, and pulp and paper chemical plants and refineries. Shell Heat Exchangers can be manufactured in a wide range of sizes, materials and designs. Shell Heat Exchangers are used in a variety of industries such as chemicals, petrochemicals, pharmaceuticals and many more.

A Shell Heat Exchanger is designed to transfer heat from one medium to another by means of convection, conduction, or radiation. They are usually made up of metal and can be used in a wide range of industries. The shell-and-tube design is the most common design for Shell Heat Exchangers.

Shell Heat Exchanger is a device used for heat transfer. It is made of metal and has a shell and tube design. Shell Heat Exchangers are also called shell and tube heat exchangers, shell and plate heat exchangers, or simply shell-and-tube exchangers.

The Shell Heat Exchanger uses fluids with different temperatures to transfer thermal energy from one fluid to the other. This process is called "heat exchange". The fluids can be water, air, oil or any other liquid or gas that changes temperature when it flows from one area to another.

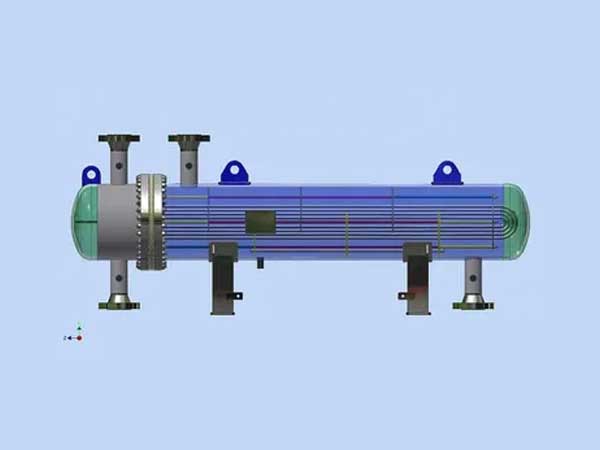

A shell and tube heat exchanger device is used to transfer thermal energy from one fluid to another fluid. The fluids are separated by a thin wall called the tube bundle. This wall serves to both contain the fluids, as well as conduct heat between them. The fluids typically flow through the tubes in opposite directions, which allows for more efficient transfer of thermal energy from one fluid to another, while maintaining better control over each individual fluid's temperature profile.

A Shell Heat Exchanger consists of two concentric pipes with a space between them called the "shell", which is filled with fluid at a lower temperature than the outer pipe. The Shell Heat Exchanger is a type of heat exchanger that is made up of two concentric pipes. The outer pipe is called the shell and the inner pipe is called the tube. They are made up of metal or composite materials and they are used to transfer heat from one fluid to another.

A Shell Heat ExchangerManufacturers is made up of two components: the shell side and the tube side. The shell side is the outermost component that transfers heat from one fluid to another. The tube side transfers the heat from the shell to the fluid that needs it most. The shell is made up of tubes that are either welded or brazed together while ensuring that no gaps exist between them.

They are usually made up of three main parts: the shell, the tube sheet and the tube. The shell is the large metal plate, which transfers heat from one fluid to another. The tube sheet is a flat metal plate that supports the tubes and keeps them in place. And finally, the tubes are hollow pipes that carry fluids through Shell Heat Exchangers.